-

Marketing and serviceCompany telephone:

Marketing and serviceCompany telephone: -

PRODUCTMarketing and serviceCompany telephone:

-

QUALITY

Marketing and serviceCompany telephone:

Marketing and serviceCompany telephone: -

Marketing and serviceCompany telephone:

Marketing and serviceCompany telephone: -

CONTACT

Marketing and serviceCompany telephone:

Marketing and serviceCompany telephone:

product

contact

Landline:+860374-6621138

Phone:+8613949836393

Phone:+8613938770929

Mailbox:fuxingzhuzao@126.com

Addres:Xiyang Industrial Zone, Changge City, Henan Province

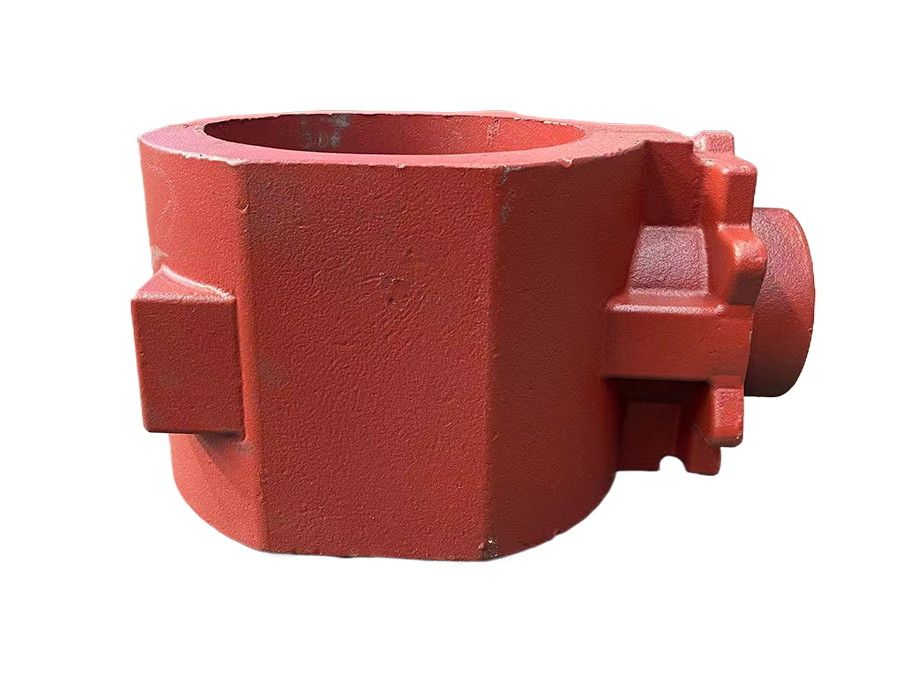

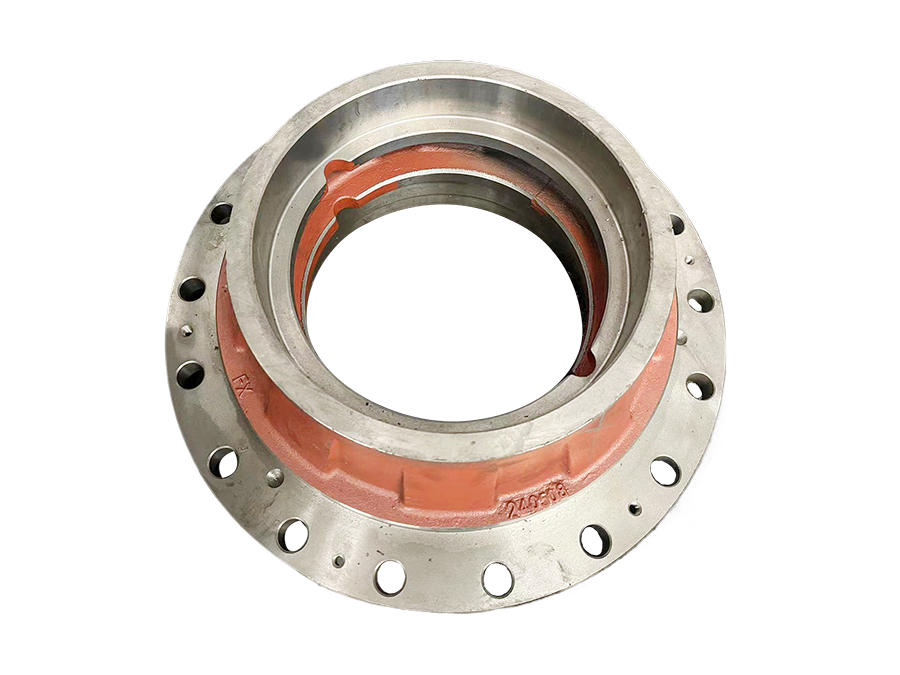

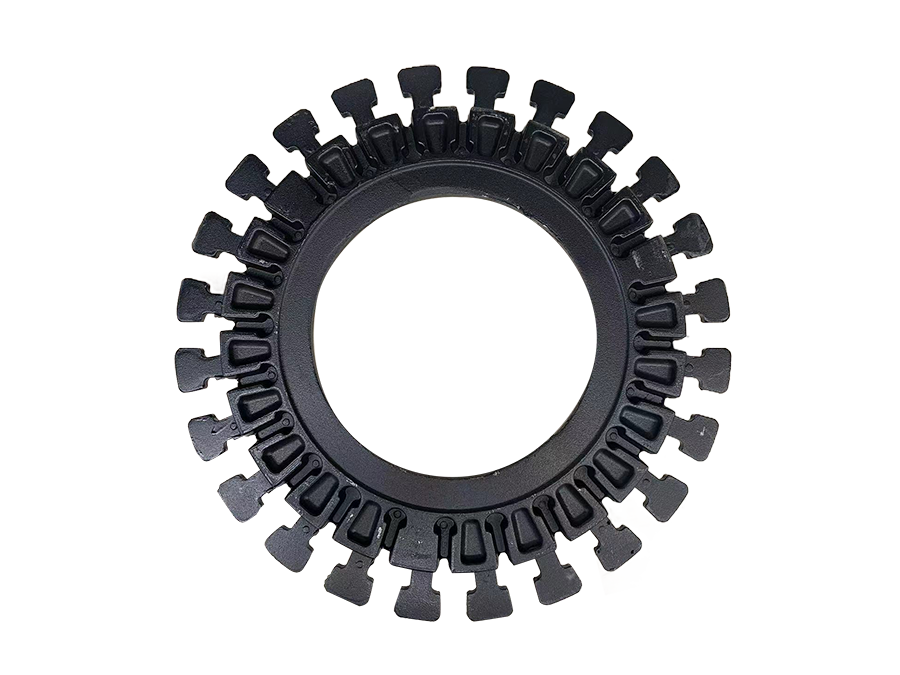

Shell

Product details

Shell, as an indispensable and important component of various mechanical equipment, electronic products, and even daily necessities, its design and manufacturing not only affect the aesthetic appearance of the product, but also directly affect the functional implementation, safety performance, and service life of the product. The shell is usually made of various materials such as metal, plastic, composite materials, etc., and is formed through precision injection molding, die casting, stamping, or 3D printing processes to meet the needs of different application scenarios.

In the field of electronic devices, the casing is not only a barrier to protect internal precision components from external interference and damage, but also a key to achieving key functions such as device heat dissipation, dust and water resistance, and signal shielding. Designers use streamlined exterior design combined with ergonomic principles to make the shell not only aesthetically pleasing but also easier for users to operate and carry. At the same time, the material selection and surface treatment process of the shell directly affect the feel and texture of the product, bringing users a more pleasant user experience.

In the automotive industry, the housing plays a crucial role, such as the engine hood, body coverings, etc. They not only need to withstand wind resistance, vibration and other tests during high-speed driving, but also need to have good sound and heat insulation performance to ensure driving comfort and safety. In addition, with the rise of new energy vehicles, the selection of housing materials is also more inclined towards lightweight and environmentally friendly, in order to further improve the energy efficiency and endurance of vehicles.

In summary, the importance of the shell as a bridge connecting the product and the user is self-evident. With the continuous advancement of technology and the increasing development of materials science, the design and manufacturing technology of shells will also continue to innovate, bringing more convenience and surprises to our lives.

keyword:

Shell

Production equipment

We currently have two fully automatic static pressure horizontal molding production lines, one 148 shock pressure molding production line, CNC machine tools, drilling, milling and other equipment, totaling more than 200 sets

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Instrumentation

We have a complete set of casting testing and inspection equipment, including over 20 high-precision testing and inspection instruments such as vacuum direct reading spectrometer and carbon sulfur analyzer

Test equipment

Test equipment

Test equipment

Test equipment

Test equipment

Test equipment

BLOG

A Discussion on the Performance and Application Fields of Ductile Iron Automotive Components

Balance Shaft Suspension: Introduction to 9 Major Application Areas

Ductile iron casting plays a crucial role in modern industrial manufacturing.

Ductile iron castings occupy a pivotal position in many industrial fields.

Ductile iron, an alloy that occupies an important position in the field of materials science!

Turbocharged vehicle maintenance: high cost of repairing core components

What technology is used to create car wheels? Is it durable and long-lasting?

How is the forging and replacement of automotive parts done?

Related products

Online Message

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

CONTACT US

Landline:+860374-6621138

Phone:+8613938770929

Mailbox:fuxingzhuzao@126.com

Address: Xiyang Industrial Zone, Changge City, Henan Province

Copyright © 2024 Changge Fuxing Auto Parts Co., Ltd

SAF Coolest v1.3.1.2 设置面板 GAGSD-ZGYF-JFAVE-ZDW

无数据提示

Sorry,当前栏目正在更新中,敬请期待!

您可以查看其他栏目或返回 首页