product

contact

Landline:+860374-6621138

Phone:+8613949836393

Phone:+8613938770929

Mailbox:fuxingzhuzao@126.com

Addres:Xiyang Industrial Zone, Changge City, Henan Province

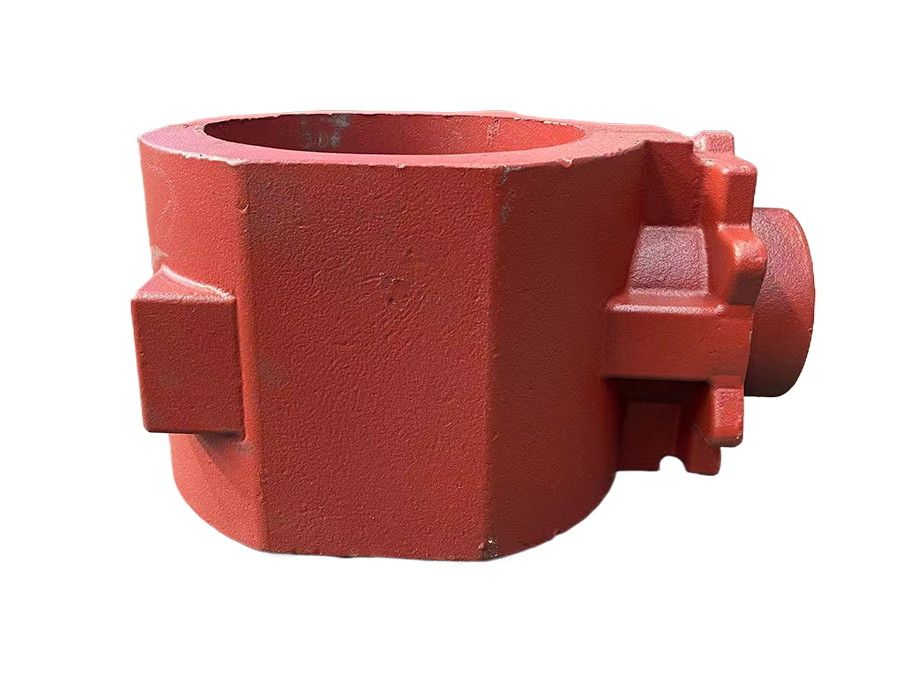

Tool magazine body

Product details

Tool magazine body

A tool magazine body is an essential component of a machining center or CNC machine tool. It is responsible for storing and changing the cutting tools that are used in the machining process. In this article, we will explore the importance of the tool magazine body, its components, and how it contributes to the efficiency and productivity of machining operations.

The tool magazine body is a crucial part of the machining center as it houses the various cutting tools needed for different machining operations. The magazine body is usually located near the spindle of the machine tool for quick and easy tool changes. It is designed to hold a range of cutting tools such as drills, end mills, reamers, and taps, allowing the machine to perform a variety of machining tasks without the need for manual tool changes.

One of the key components of the tool magazine body is the tool carousel or tool changer. This is a rotating mechanism that allows the machine to automatically select and change tools during the machining process. The tool carousel typically consists of multiple tool pockets or slots where the cutting tools are stored. The carousel can rotate in both horizontal and vertical directions to bring the desired tool to the spindle for tool change.

In addition to the tool carousel, the tool magazine body also includes a tool gripper or tool changer arm. This is a robotic arm that is used to grip and release the cutting tools from the tool carousel. The tool gripper is equipped with sensors and actuators that allow it to accurately position and secure the tool in the spindle. The tool gripper is controlled by the machine's CNC system, which sends commands to the arm to perform tool changes as required.

Another important component of the tool magazine body is the tool identification system. This system uses RFID tags, barcodes, or other identification methods to track and manage the cutting tools stored in the magazine. Each tool is assigned a unique identifier that is linked to its geometry, material, wear status, and other relevant information. This allows the machine to automatically select the correct tool for a specific machining operation based on the tool data stored in the system.

The tool magazine body plays a significant role in improving the efficiency and productivity of machining operations. By automating the tool changing process, the machine can reduce downtime and operator intervention, leading to faster cycle times and increased throughput. The ability to store multiple tools in the magazine also allows the machine to perform complex machining tasks without the need for manual tool changes, resulting in higher precision and accuracy in the finished parts.

In conclusion, the tool magazine body is a critical component of a machining center or CNC machine tool. It enables the machine to store, select, and change cutting tools automatically, improving efficiency, productivity, and accuracy in machining operations. By understanding the importance of the tool magazine body and its components, manufacturers can optimize their machining processes and achieve better results in their production operations.

keyword:

Tool magazine body

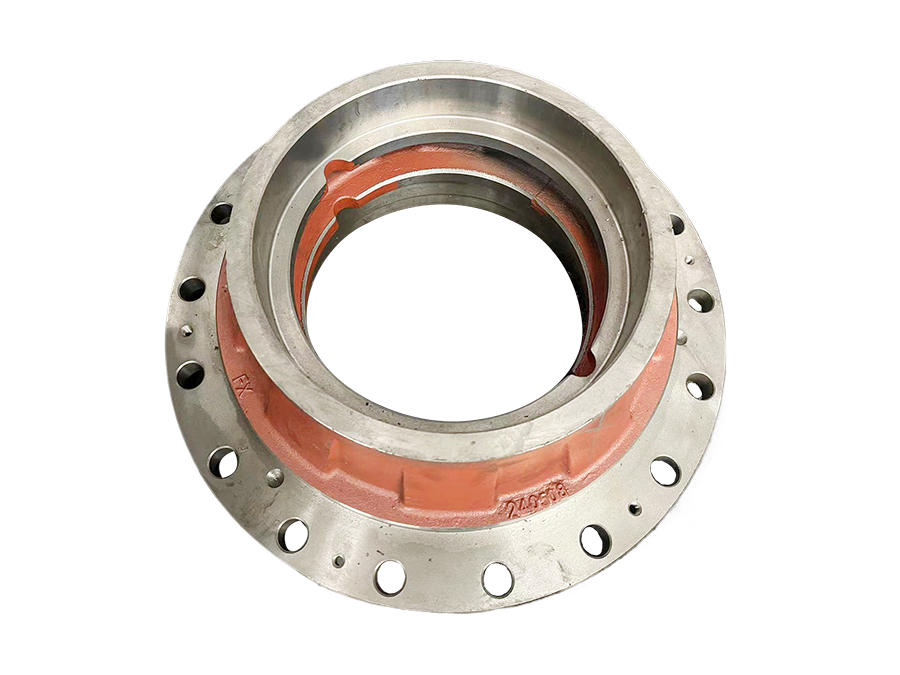

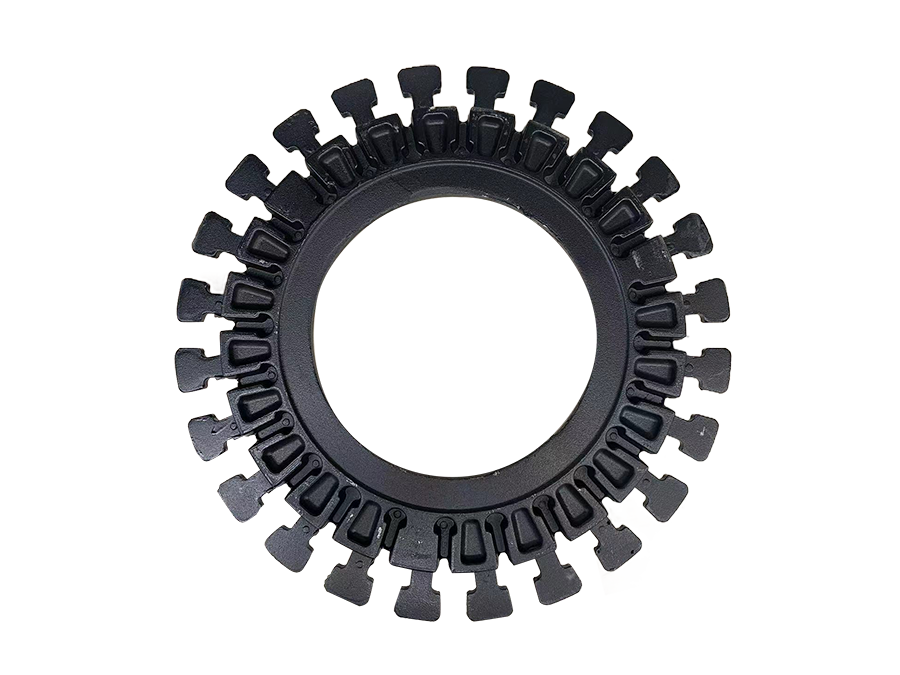

Production equipment

We currently have two fully automatic static pressure horizontal molding production lines, one 148 shock pressure molding production line, CNC machine tools, drilling, milling and other equipment, totaling more than 200 sets

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Instrumentation

We have a complete set of casting testing and inspection equipment, including over 20 high-precision testing and inspection instruments such as vacuum direct reading spectrometer and carbon sulfur analyzer

Test equipment

Test equipment

Test equipment

Test equipment

Test equipment

Test equipment

BLOG

Ductile iron casting plays a crucial role in modern industrial manufacturing.

Ductile iron castings occupy a pivotal position in many industrial fields.

Ductile iron, an alloy that occupies an important position in the field of materials science!

Turbocharged vehicle maintenance: high cost of repairing core components

What technology is used to create car wheels? Is it durable and long-lasting?

How is the forging and replacement of automotive parts done?

Related products

Online Message

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.