product

contact

Landline:+860374-6621138

Phone:+8613949836393

Phone:+8613938770929

Mailbox:fuxingzhuzao@126.com

Addres:Xiyang Industrial Zone, Changge City, Henan Province

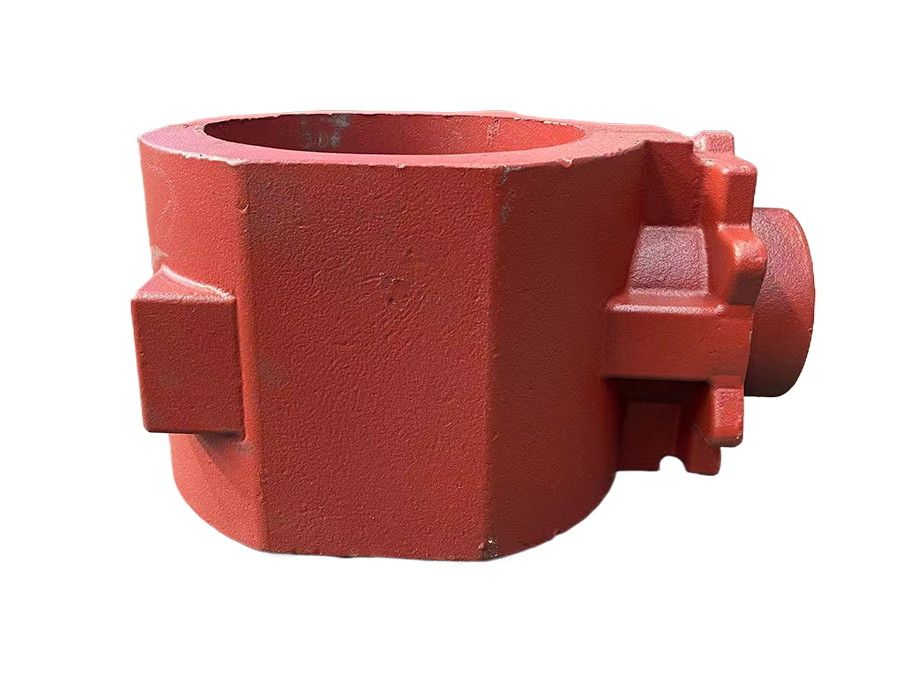

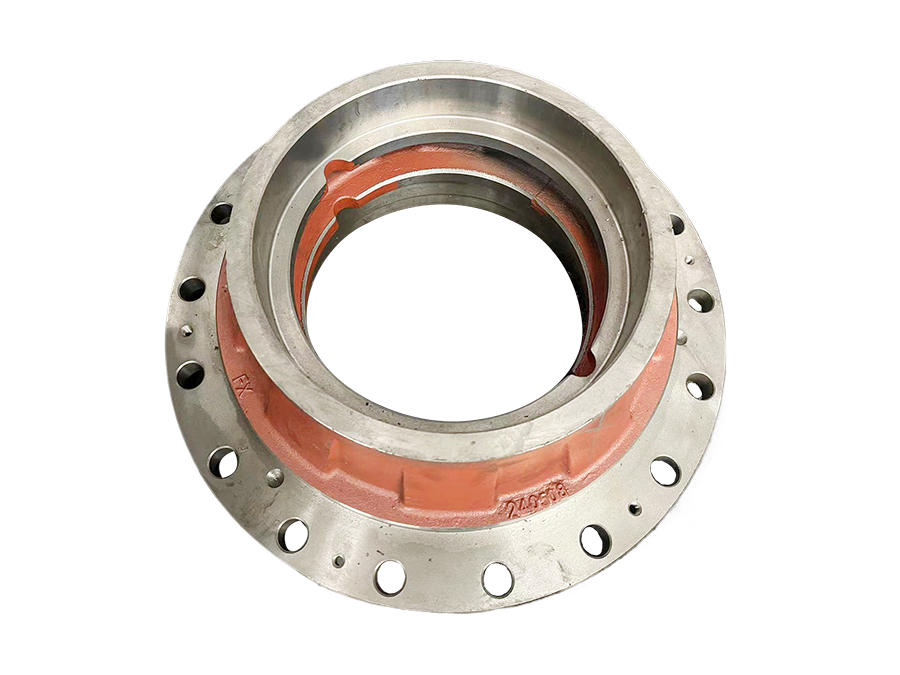

Wheel hub

Product details

Wheel hub

A wheel hub, also known as a wheel bearing assembly, is a crucial component of a vehicle's wheel system. It is responsible for supporting the weight of the vehicle, providing a smooth and stable ride, and enabling the wheels to rotate freely. In this article, we will explore the importance of wheel hubs, how they work, and the common issues that can arise with them.

The wheel hub is located at the center of the wheel and is connected to the vehicle's suspension system. It consists of several components, including the hub, bearings, seals, and sometimes the wheel speed sensor. The hub is the central part that attaches to the axle, while the bearings allow the wheel to rotate smoothly. The seals prevent dirt, water, and other contaminants from entering the wheel hub and causing damage. The wheel speed sensor, if present, monitors the speed of the wheel and sends data to the vehicle's computer system.

One of the key functions of the wheel hub is to support the weight of the vehicle and provide a smooth ride. As the vehicle moves, the wheel hub rotates along with the wheel, distributing the weight of the vehicle evenly across the bearings. This helps reduce friction and wear on the tires, suspension, and other components of the vehicle. A properly functioning wheel hub ensures that the vehicle remains stable and safe to drive.

In addition to supporting the weight of the vehicle, the wheel hub also allows the wheels to rotate freely. The bearings inside the wheel hub are lubricated to reduce friction and enable smooth rotation. This allows the wheels to move freely without resistance, improving fuel efficiency and overall performance. A damaged or worn wheel hub can cause the wheels to wobble or make a grinding noise, indicating that it needs to be replaced.

Despite their importance, wheel hubs can experience issues over time due to wear and tear, improper installation, or lack of maintenance. Common problems with wheel hubs include worn bearings, damaged seals, and faulty wheel speed sensors. Worn bearings can cause the wheels to wobble or make a humming noise, while damaged seals can lead to leaks and contamination. A faulty wheel speed sensor can cause issues with the vehicle's ABS system and affect the overall performance of the vehicle.

To prevent issues with wheel hubs, it is important to perform regular maintenance and inspections. This includes checking for signs of wear, lubricating the bearings, and replacing any damaged components. If you notice any unusual noises or vibrations coming from the wheels, it is important to have the wheel hubs inspected by a professional mechanic. Ignoring wheel hub issues can lead to more serious problems and put your safety at risk.

In conclusion, wheel hubs are a critical component of a vehicle's wheel system, responsible for supporting the weight of the vehicle, providing a smooth ride, and enabling the wheels to rotate freely. By understanding the importance of wheel hubs, how they work, and common issues that can arise, you can take the necessary steps to ensure your vehicle remains safe and reliable on the road. Remember to perform regular maintenance and inspections to keep your wheel hubs in optimal condition.

keyword:

Wheel hub

Production equipment

We currently have two fully automatic static pressure horizontal molding production lines, one 148 shock pressure molding production line, CNC machine tools, drilling, milling and other equipment, totaling more than 200 sets

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Instrumentation

We have a complete set of casting testing and inspection equipment, including over 20 high-precision testing and inspection instruments such as vacuum direct reading spectrometer and carbon sulfur analyzer

Test equipment

Test equipment

Test equipment

Test equipment

Test equipment

Test equipment

BLOG

Ductile iron casting plays a crucial role in modern industrial manufacturing.

Ductile iron castings occupy a pivotal position in many industrial fields.

Ductile iron, an alloy that occupies an important position in the field of materials science!

Turbocharged vehicle maintenance: high cost of repairing core components

What technology is used to create car wheels? Is it durable and long-lasting?

How is the forging and replacement of automotive parts done?

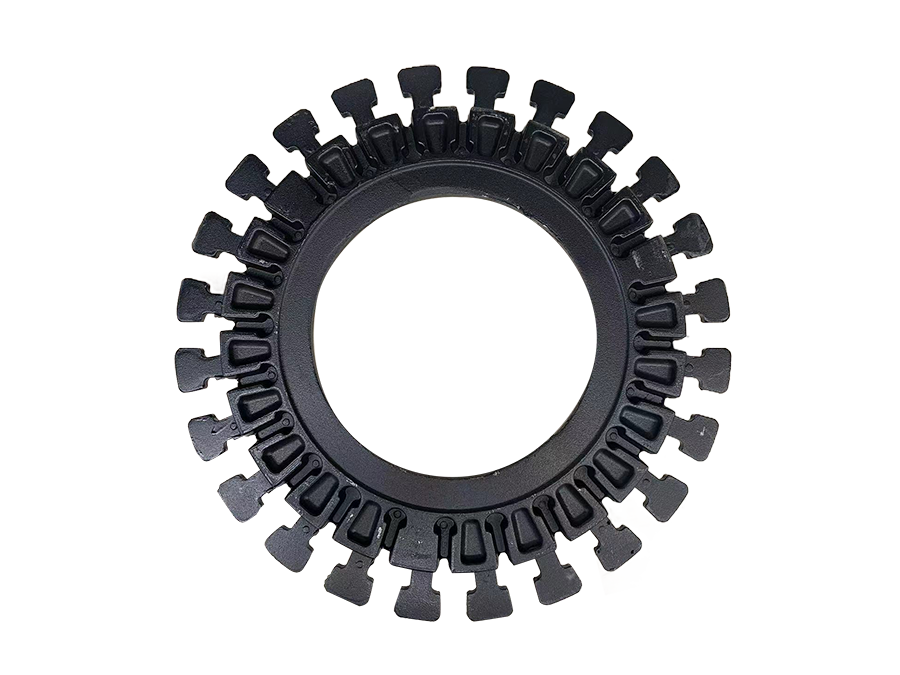

Related products

Online Message

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.