product

contact

Landline:+860374-6621138

Phone:+8613949836393

Phone:+8613938770929

Mailbox:fuxingzhuzao@126.com

Addres:Xiyang Industrial Zone, Changge City, Henan Province

Reducer parts

Product details

Reducer parts

Reducers are essential components in many mechanical systems, often used to decrease the speed of rotating machinery while increasing torque. They consist of several parts, each with a specific function that contributes to the overall performance of the reducer. In this article, we will discuss the different parts of a reducer and their roles in the system.

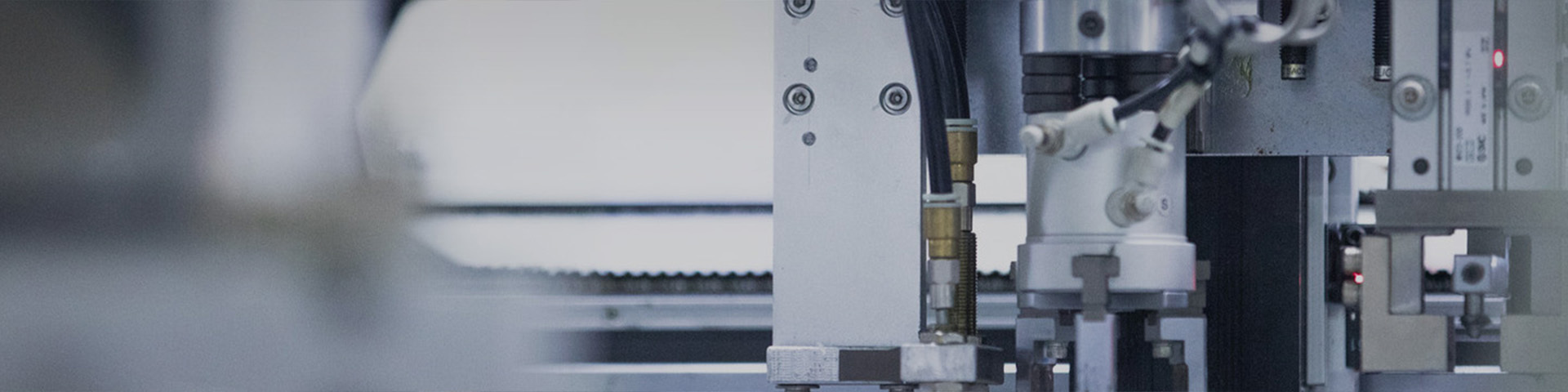

1. Housing

The housing is the outer casing of the reducer, providing protection and support for the internal components. It is typically made of cast iron or aluminum to withstand the mechanical stresses and environmental conditions. The housing also serves as a mounting point for the input and output shafts, as well as the bearings that support them.

2. Input shaft

The input shaft is connected to the driving source, such as an electric motor or an engine. It transmits rotational motion to the reducer, which then reduces the speed and increases the torque before transferring the power to the output shaft. The input shaft is usually made of high-strength steel to withstand the torque and bending forces exerted on it.

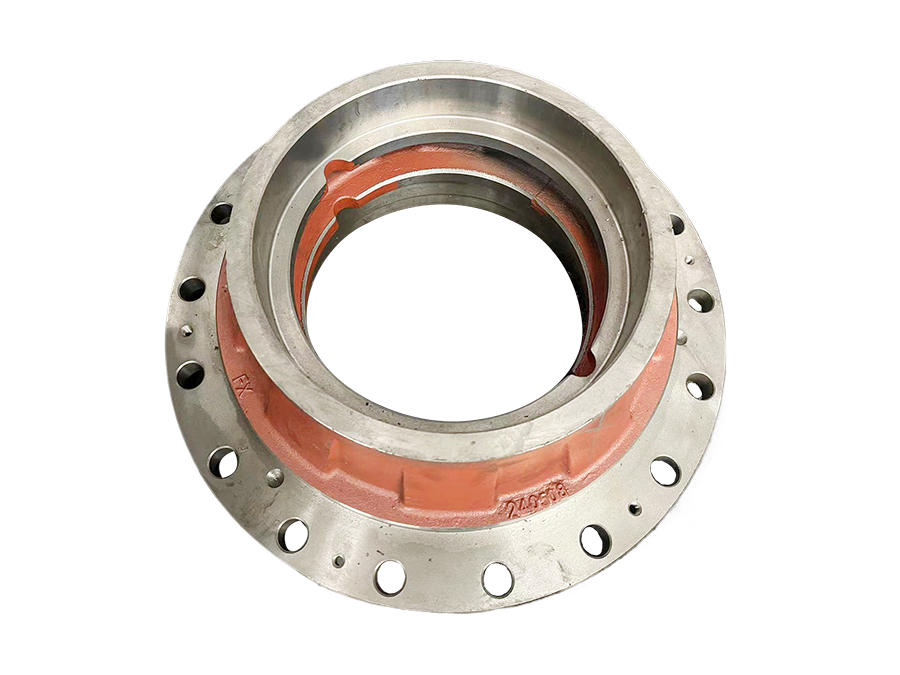

3. Gears

Gears are the heart of the reducer, responsible for transmitting power from the input shaft to the output shaft. There are various types of gears used in reducers, such as spur gears, helical gears, bevel gears, and worm gears, each with its unique advantages and applications. The gear teeth are precision-machined to ensure smooth and efficient power transmission.

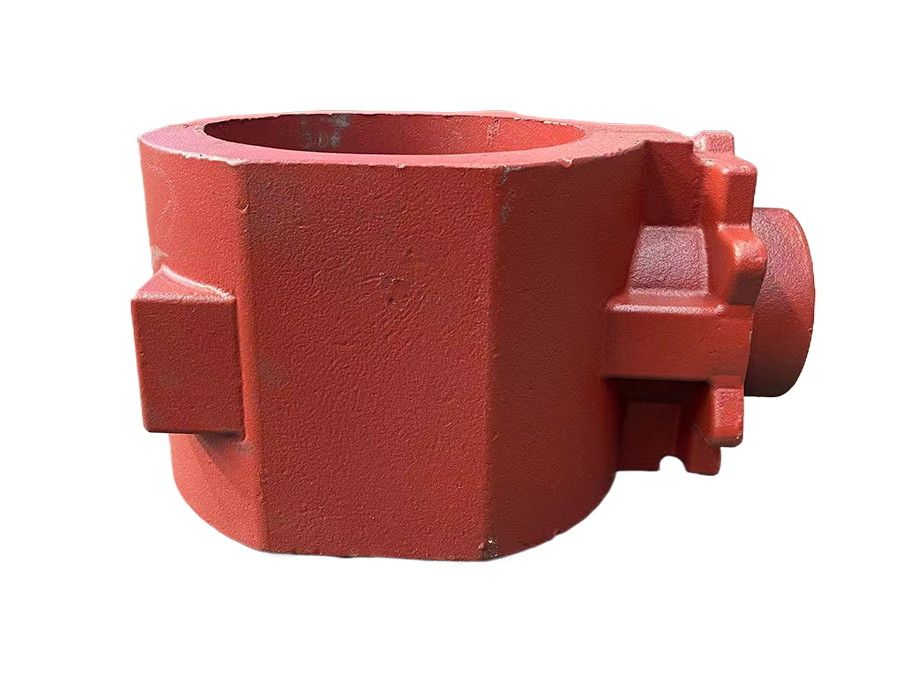

4. Bearings

Bearings are crucial components in reducers, supporting the rotating shafts and reducing friction between moving parts. They help to maintain the alignment of the shafts and prevent excessive wear and heat generation. High-quality bearings are essential for the smooth operation and longevity of the reducer.

5. Output shaft

The output shaft receives the power from the gears and transmits it to the driven equipment, such as a conveyor belt or a gearbox. Like the input shaft, the output shaft is made of durable materials to withstand the torque and bending forces. It is usually connected to the driven equipment through couplings or other mechanical attachments.

6. Seals

Seals are used to prevent lubricant leakage and contamination in the reducer. They are typically made of rubber or synthetic materials and are placed at the interfaces between the housing and the shafts. Proper sealing ensures the efficient operation of the reducer and extends its service life by protecting the internal components from dirt, moisture, and other contaminants.

In conclusion, reducers consist of several essential parts that work together to transmit power efficiently and reliably. Understanding the roles of each component helps in selecting the right type of reducer for a specific application and ensuring its proper maintenance and operation. By paying attention to the design and quality of the reducer parts, users can maximize the performance and longevity of their mechanical systems.

keyword:

Reducer parts

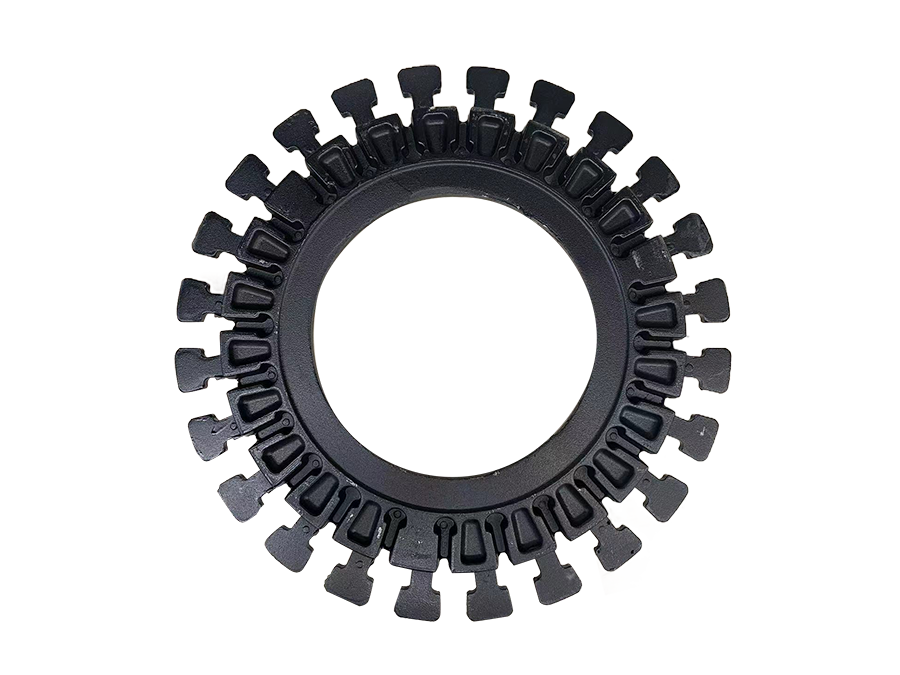

Production equipment

We currently have two fully automatic static pressure horizontal molding production lines, one 148 shock pressure molding production line, CNC machine tools, drilling, milling and other equipment, totaling more than 200 sets

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Instrumentation

We have a complete set of casting testing and inspection equipment, including over 20 high-precision testing and inspection instruments such as vacuum direct reading spectrometer and carbon sulfur analyzer

Test equipment

Test equipment

Test equipment

Test equipment

Test equipment

Test equipment

BLOG

A Discussion on the Performance and Application Fields of Ductile Iron Automotive Components

Balance Shaft Suspension: Introduction to 9 Major Application Areas

Ductile iron casting plays a crucial role in modern industrial manufacturing.

Ductile iron castings occupy a pivotal position in many industrial fields.

Ductile iron, an alloy that occupies an important position in the field of materials science!

Turbocharged vehicle maintenance: high cost of repairing core components

What technology is used to create car wheels? Is it durable and long-lasting?

How is the forging and replacement of automotive parts done?

Related products

Online Message

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.