product

contact

Landline:+860374-6621138

Phone:+8613949836393

Phone:+8613938770929

Mailbox:fuxingzhuzao@126.com

Addres:Xiyang Industrial Zone, Changge City, Henan Province

Axle housing parts

Product details

Axle housing parts

Axle housing is an essential component of a vehicle's suspension system, providing support and protection for the axle shafts and bearings. It plays a crucial role in maintaining the stability and structural integrity of the vehicle. In this article, we will explore the various parts that make up the axle housing and their functions.

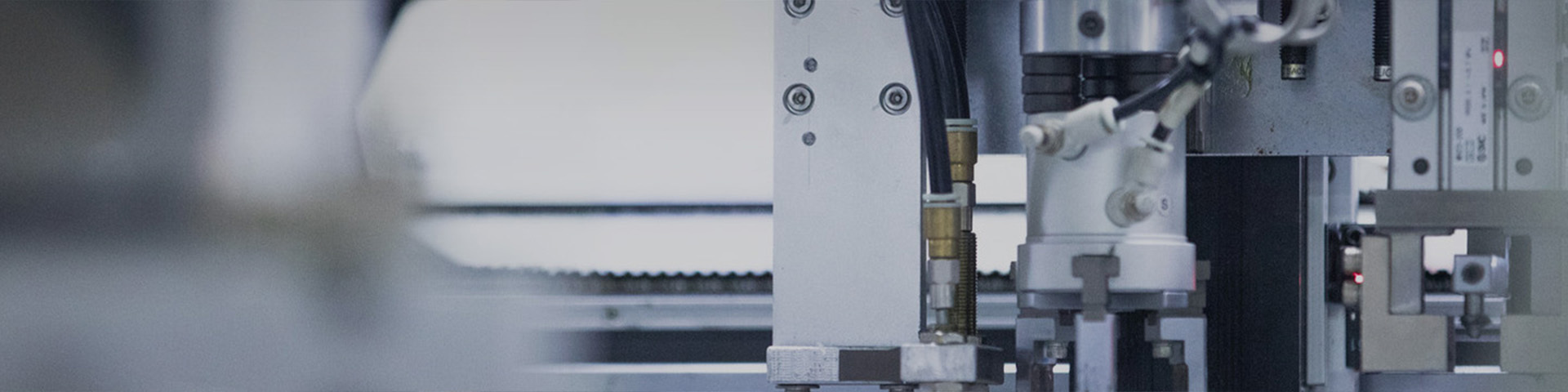

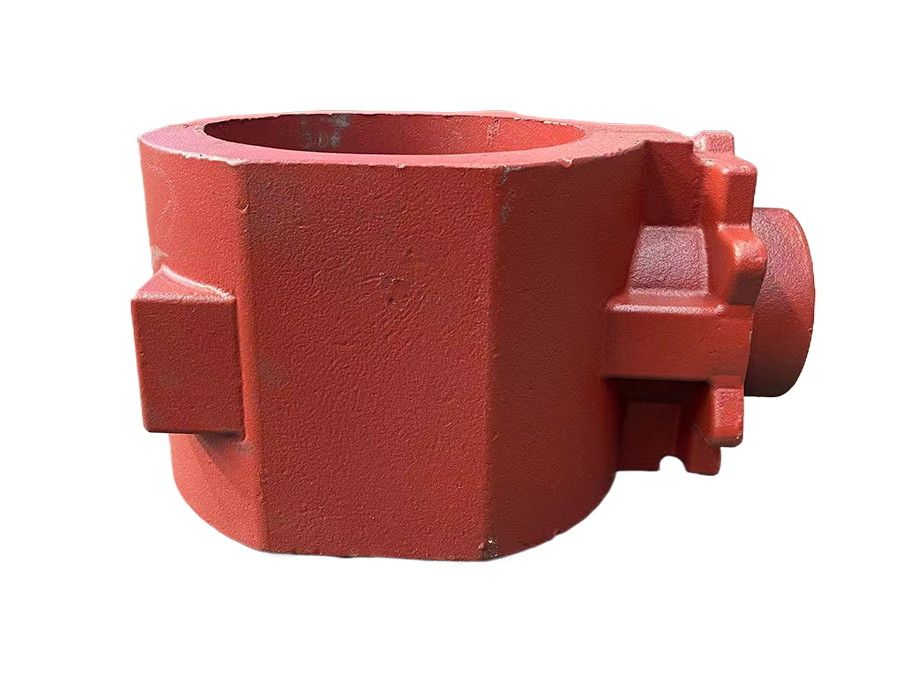

1. Housing

The main body of the axle housing is typically made of cast iron or steel to withstand the weight and stress of the vehicle. It is designed to encase the axle shafts and bearings, providing a secure and stable environment for them to operate. The housing also serves as a mounting point for the suspension components and other parts of the vehicle.

2. Axle shafts

The axle shafts are the primary load-carrying components of the axle housing, transferring power from the differential to the wheels. They are usually made of high-strength steel to withstand the torque and bending forces generated by the vehicle. The axle shafts are connected to the differential at one end and the wheels at the other end, allowing the wheels to rotate and move the vehicle forward.

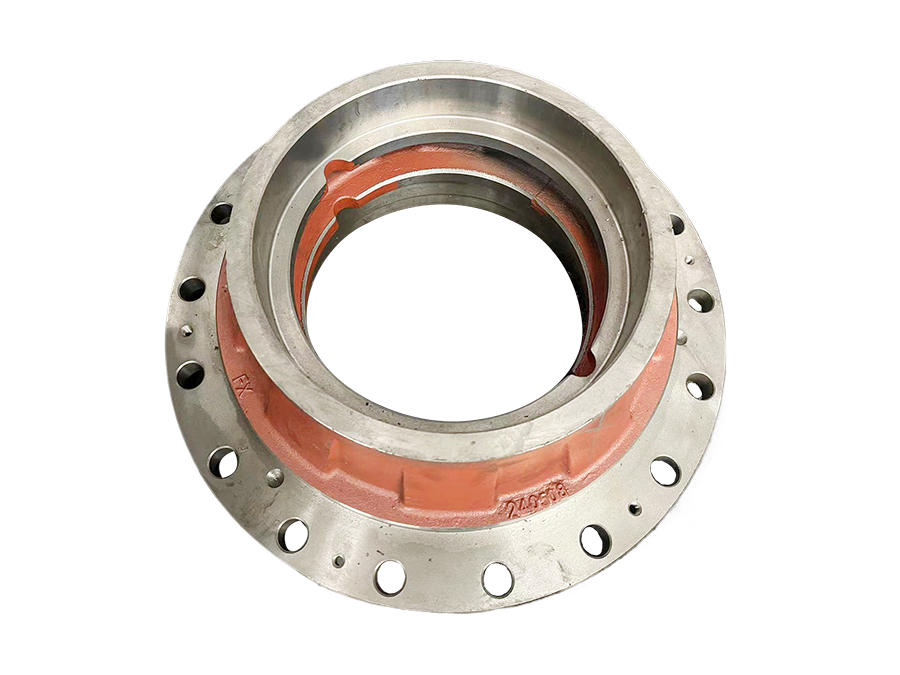

3. Bearings

The axle housing contains several bearings that support and guide the axle shafts as they rotate. These bearings reduce friction and wear on the axle shafts, allowing them to operate smoothly and efficiently. The bearings are typically made of high-quality steel or other durable materials to withstand the forces and pressures exerted on them during operation.

4. Differential

The differential is a crucial component of the axle housing, distributing power from the transmission to the axle shafts and wheels. It allows the wheels to rotate at different speeds while maintaining equal torque and power distribution. The differential is typically located within the axle housing and is connected to the axle shafts through a series of gears and shafts.

5. Seals and gaskets

The axle housing contains several seals and gaskets to prevent the leakage of oil and other fluids from the housing. These seals and gaskets are typically made of rubber or silicone to provide a tight seal and prevent contamination of the axle components. They are essential for maintaining the proper lubrication and operation of the axle housing.

6. Mounting brackets

The axle housing is equipped with mounting brackets and hardware to secure it to the vehicle's frame and suspension components. These brackets provide support and stability for the axle housing, preventing it from shifting or moving during operation. They are typically made of steel or other durable materials to withstand the forces and stresses exerted on them.

In conclusion, the axle housing is a critical component of a vehicle's suspension system, providing support and protection for the axle shafts and bearings. It is made up of various parts, including the housing, axle shafts, bearings, differential, seals, gaskets, and mounting brackets. Each of these components plays a crucial role in maintaining the stability and structural integrity of the vehicle. By understanding the functions and characteristics of these axle housing parts, vehicle owners can ensure the proper maintenance and operation of their vehicles.

keyword:

Axle housing parts

Production equipment

We currently have two fully automatic static pressure horizontal molding production lines, one 148 shock pressure molding production line, CNC machine tools, drilling, milling and other equipment, totaling more than 200 sets

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Production Equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Processing equipment

Instrumentation

We have a complete set of casting testing and inspection equipment, including over 20 high-precision testing and inspection instruments such as vacuum direct reading spectrometer and carbon sulfur analyzer

Test equipment

Test equipment

Test equipment

Test equipment

Test equipment

Test equipment

BLOG

A Discussion on the Performance and Application Fields of Ductile Iron Automotive Components

Balance Shaft Suspension: Introduction to 9 Major Application Areas

Ductile iron casting plays a crucial role in modern industrial manufacturing.

Ductile iron castings occupy a pivotal position in many industrial fields.

Ductile iron, an alloy that occupies an important position in the field of materials science!

Turbocharged vehicle maintenance: high cost of repairing core components

What technology is used to create car wheels? Is it durable and long-lasting?

How is the forging and replacement of automotive parts done?

Related products

Online Message

If you have any suggestions, please leave a message or send an email to us, and we will reply to you within 1 working day after receiving the message email.